Pneumatic Tools VS Electric Power Tools

When it comes to pneumatic air tools and electric power tools, there are significant differences in terms of strength, characteristics, and cost. Both pneumatic tools and electric tools are engineered with industrial grade quality and offer similar functions with excellent performance for various job applications. In this article, we are going to discover the differences and comparisons between these two types of power tools. Having a thorough understanding of these different types of power tools will help you in choosing the right tools for your project.

Pneumatic Power Tools

|

Pneumatic tools, also known as air tools, require compressed air to run the power tools instead of mechanical force. They are strong power tools that deliver greater torque and high power when attached to an air compressor. The pneumatic tools provide reliable operation in heavy duty applications on a variety of tasks.

Pneumatic tools are more powerful than electric tools as air compressors create substantial power by compressing and condensing air that produces bursts of energy. As a result of this excess energy, pneumatic tools are extremely powerful and more often than not, far superior than electric tools when it comes to power.

Pneumatic tools are relatively smaller and lighter than the traditional electric power tools as they do not have a main motor installed. Hence, these pneumatic tools offer better power-to-weight-ratio, allowing lighter and smaller air tools to produce more power than electric ones.

Compared to electric power tools, pneumatic tools are safer to use than electric power tools. The pneumatic tools offer a higher degree of safety and are easy to handle under extreme conditions. Unlike electric tools, there is no danger of electric shock for pneumatic tools as some models such as underwater air tools can be used around water. Therefore, pneumatic tools are more ideal for use in hazardous or explosive environments such as oil refineries.

Once last important point about pneumatic tools is that they are typically easier to maintain and often last longer than electric ones due to lesser parts used in the machine itself, making them more reliable.

Although pneumatic tools are often lighter and easier to handle, they are not as portable compared to electric ones as they require an air compressor to operate. This can be a nuisance as it requires carrying an extra piece of equipment around when doing simple tasks as well as maintaining the compressor so that it keeps generating enough pressure. Hence, it may not be convenient to transport to remote work sites. In addition, the initial investment costs of pneumatic tools are higher as users will be required to get an air compressor equipment to operate the pneumatic tools.

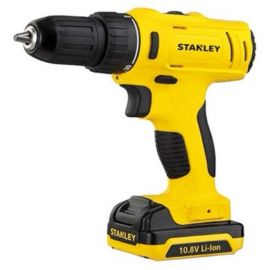

Electric Power Tools

|

Electric power tools are driven by motors that require electricity from either a power cord or battery. They require a constant supply of electricity as motive power. There are two types of electric power tools that are available and quite popular in the market: corded and cordless power tools. Corded power tools require an extension cord and plug to keep them running, while cordless power tools will require a rechargeable battery attached to the tools to operate.

As compared to pneumatic tools, electric power tools are heavier due to the attachment of batteries or their electrical cables. However, electric power tools offer greater portability and versatility as they are operated by electricity, be it by electrical cables or batteries, they do not require other cumbersome equipment such as an air compressor to power them. They are highly portable to use in both indoor and outdoor environments; therefore, making them easy to handle and can be transported from one work site to another with ease.

In addition, electric power tools tend to have lower revolutions per minute (RPM), and hence they typically require more time to complete a task. Moreover, electric tools have a shorter life span compared to pneumatic tools as wear and tear on the motor and parts are common. The batteries of the cordless power tools can also run out quickly and wear out over time. Regular maintenance and inspection on electric tools are necessary to ensure they function properly.

On a positive note, as electric power tools do not require extra equipment to power them, they are cheaper than pneumatic tools and require less investment. Users only need to purchase the rechargeable battery for cordless tools or opt for corded electrical versions.

Having explored the above comparisons, let's summarize them. When it comes to safety, pneumatic tools will be a great choice as users do not have to deal with electrical risks. However, electric power tools will be your best choice if portability and convenience are your top priorities.

As a leading and established industrial tools supplier with decades of experience, Chee Fatt has decades of experience in distributing and stocking a wide range of high quality and reliable industrial pneumatic tools and electric tools to meet all industrial needs. From drilling tools to heavy duty cutters, Chee Fatt has a variety of pneumatic tools Singapore and electric power tools from all the trusted and renowned brands worldwide. Look no further, start exploring our website to learn more!

Pneumatic Tools >> bit.ly/3pp4en3

Electric Power Tools >> bit.ly/3PKONk3

2364

2364