7 Types Of Abrasive Discs And Their Characteristics

Abrasive Discs are circular portable tools that are generally made of high-abrasive materials for precision cutting, grinding, smoothing, finishing, or sanding different types of material surfaces by generating a form of mechanical or friction action. However, there are different types of abrasive discs with various designs, shapes, sizes, and functions for different applications. To make the right choice for your specific application, it is important and essential to understand the differences and characteristics of these abrasive discs.

1. Flat Cutting Discs

|

Flat Cutting Discs, also known as Cut-Off Wheels, are standard, flat, thin, and circular abrasive discs engineered to provide a quality, durable and long-lasting cutting performance when cutting through materials such as wood, ceramic, stainless steel (Inox), steel, aluminium, iron, and stone. These cutting discs are often made of highly abrasive materials such as aluminium oxide or silicon carbide. These high abrasive discs come with a range of thickness from 0.8mm to a maximum of 4mm and usually offer a variety of grit sizes from 24 to 120, providing excellent and maximum precision cutting solutions for many industrial applications. The flat type cutting disc is ideal for larger contact areas at an optimum angle of 0-15°. For standard light duty tasks, a thinner disc will be your best choice. Whereas thicker and larger discs are ideal for heavy duty applications and offer a longer tool life. Browse here for more Flat Cutting Discs: bit.ly/3tcbi9x |

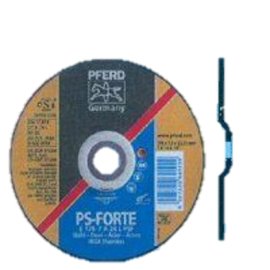

2. Depressed Centre Cutting Discs

|

Depressed Centre Cutting Discs serve a similar purpose to Flat Cutting Discs for cutting through a range of materials, but their outer shapes are different. A standard cutting disc is flat in shape. Depressed Centre Cutting Discs, also referred to as raised hub wheels are designed with a concave shape at the centre, or the centre is depressed. Their unique concave shape is ideal for curved workpiece, uneven surfaces and perform high cutting performance at any areas that are narrow or difficult to reach. Browse here for more Depressed Centre Cutting Discs: bit.ly/3H2NZDt |

3. Diamond Cutting Wheels

|

One of the most common questions related to this type of wheel is….. ‘’Are diamond cutting wheels made of diamond?’’. The short answer is no. Diamond Cutting Wheels, also known as Diamond Blades, are super abrasive wheels coated with diamond crystals on its cutting edge. The diamond crystals used are synthetic diamonds rather than natural diamonds. Synthetic diamond crystals are one of the hardest materials available as it is manufactured through high pressure and high temperature processes. With cutting-edge technology, diamond cutting wheels made of such materials prolong tool life and enhance its quality. There are three types of shapes for the diamond cutting wheels: segmented rim, continuous rim, and turbo rim.

Browse here for more Diamond Cutting Wheels: bit.ly/34c2UMI |

4. Flat Grinding Discs

|

Flat Grinding Discs also known as Grinding Wheels, are a type of durable and circular abrasive disc containing abrasive grains for grinding and removing materials from the workpiece surface in small chips. It can be operated with an angle grinder to perform any grinding tasks with high performance and achieve particularly high stock removal rates when working on certain materials such as stainless steel (Inox), steel, aluminium or iron. When choosing a grinding disc, it is important to consider the grit sizes and diameters. These grinding discs come with a range of grit sizes from 24 to 120 and a large range of diameters, providing excellent grinding tasks for various industrial applications. The larger the grit size, the finer the abrasive particles. The flat type grinding disc is ideal for larger contact areas at an optimum angle of 0-15° for surface grinding. Browse here for more Flat Grinding Discs: bit.ly/3u0hNwx |

5. Depressed Centre Grinding Discs

|

Depressed Centre Grinding Discs serve a similar purpose to Flat Grinding Discs which perform grinding tasks on certain materials’ surface, but their outer shapes are different. Depressed Centre Grinding Discs, also referred to as raised hub wheels are designed with a concave shape at the centre, or the centre is depressed. Their unique concave shape is ideal for curved workpiece, uneven surfaces and performs grinding tasks at any areas that are narrow or difficult to reach. Additionally, they are also suitable for shaping and rebating, chamfering, facing, and profiling either on horizontal or vertical surfaces. Browse here for more Depressed Centre Grinding Discs: bit.ly/3AxGqly |

6. Sanding Discs

|

Sanding discs are one of the essential tools for machining or fabrication works. Sanding discs are circular abrasive discs specially used for smoothing edges, finishing, or removing materials usually due to light defects or corrosion. The sanding discs are available in different sizes, grades, and grit sizes from 24 to 600 to meet various industrial applications. Often these discs will need to be attached onto a backing pad so that they can be mounted onto a sander, angle grinder or other tools to operate efficiently. Sanding discs are one of the most cost economical sanding solutions in the market now. Browse here for more Sanding Discs: bit.ly/3reX84X |

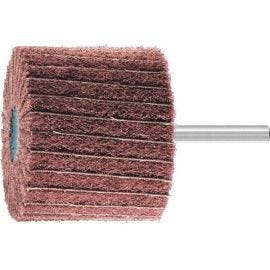

7. Flap Wheels

|

Flap Wheels are versatile circular abrasive tools engineered with high quality coated abrasive materials to provide consistent grinding and finishing on various materials including stainless steel (Inox), steel, iron, and other non-ferrous metals. Typically, the flap wheels are mounted to the tool and arranged in a fan-like structure around their centre axis. The rough surface on flap wheels help to produce a finer surface and excellent finishing. Flap wheels are available in a wide range of diameters, shapes and grit sizes depending on the applications. They can be attached to most straight grinders or power drills. Browse here for more Flap Wheels: bit.ly/3rRvj31 |

Are you looking for a reliable abrasive tool with a long tool life? As an authorized distributor of abrasive tools in the region, Chee Fatt Company has a decade of experience in distributing a wide range of high-quality and reliable abrasive and polishing tools from renowned brands to meet different industrial applications. We carry a full line of abrasives from light duty sanding paper to heavy duty grinding discs. To check out more abrasive tools, browse our official website now: bit.ly/3qmdsl6

Drop us a line and let us know how we can assist you with your abrasives requirement.

9224

9224