Choose the Right Drill Bit for the Job

Understanding when and which drill bit to use is essential for ensuring a job is completed accurately on the first attempt. With a myriad of drill bit types tailored for various tasks, the sheer variety can be daunting. Familiarity with their functions is paramount for achieving success in any project.

For those new to drilling or seeking information on drill bits, you're in luck. Chee Fatt offers the comprehensive guide to purchasing and using drill bits, simplifying the process for you. Let’s explore why this production tool is essential for us to enhance any drilling effortlessly.

Drill Bits: What It Is?

Drill bits are essential cutting tools used in conjunction with a drill machine to create holes in various materials. These cylindrical or conical-shaped tools are constructed or prepared with high-speed steel, cobalt, carbide, or sometimes even diamond based on applications.

The drill bits are generally divided into flute, tip, and body along with shank. Because drill bits come in a variety of sizes, hole diameters can be precisely customized to meet project-specific requirements. So, these tools accurately and confidently shape and fit a huge number of structures and components in both manufacturing and construction, as in do-it-your-yourself projects.

Types of Drill Bits

|

|

|

|

|

|

|

|

|

|

Factors to Consider

Material Compatibility

Various drill bits are engineered to handle specific materials like wood, metal, plastic, or masonry, each possessing distinct characteristics that necessitate a matching drill bit for optimal drilling results· Drill bits for wood often feature a pointed, sharp tip designed to penetrate wood fibers smoothly to prevent splintering· In contrast, metal drill bits are made from robust materials such as high-speed steel or cobalt to withstand the rigors and heat generated when drilling through metallic surfaces.

Bit Type and Size

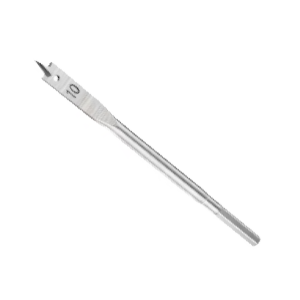

The selection of drill bits depends on the required hole characteristics and the mate rial involved. Twist bits, known for their adaptability, are optimal for a wide range of drilling duties. For creating substantial holes in wood, spade bits are preferable. Hole saws excel at making precise, circular holes in various materials. In contrast, masonry bits, typically tipped with carbide or diamond, are specifically engineered to penetrate concrete, brick or stone. Selecting the appropriate drill bit diameter is equally crucial to avoid mistakes or potential harm to the material being drilled.

Shank Type

The shank of the drill bit refers to the part that fits into the chuck of the drill. It's important to match the shank type to your drill machine to ensure compatibility and secure attachment. Common shank types include round, hexagonal, and SDS (Special Direct System) for rotary hammer drills. Choosing the right shank type ensures smooth operation and prevents slippage or wobbling during drilling.

Speed and Feed Rate

Achieving optimal drilling results hinges on operating the drill at the correct speed and feed rate. Specific speed settings correspond to various materials and drill bit types to prevent issues like overheating or premature wear. While general rules exist, referring to drill bit charts or manufacturer guidelines ensures precise drilling parameters for your needs. This customized approach not only prolongs drill bit lifespan but also reduces the risk of damaging the workpiece. For improved performance, particularly with challenging materials, using lubricants or coolants is strongly advised.

Tips for Safety

- Put on your safety glasses and gloves when using power tools.

- Keep your drill bits in the best state possible.

- Secure workpiece properly so that it is not moving during the drilling process, as this might create wrong holes and cause injury.

- Choose from well-known drill bit brands and invest in quality for long life and good performance.

- Verify that your drill bit is appropriate for the material and thickness you are working with.

- Utilize lubrication or cooling methods, especially when drilling into metals, to prolong the life of your drill bits

- Use a pilot hole for precise drilling and to prevent wandering of the drill bit on smooth surfaces

- Clean and inspect your drill bits after each use to remove debris and ensure they're in good condition

Wrapping It Up

Selecting the appropriate drill bit is crucial for attaining professional-grade results in every drilling endeavor. By comprehending the materials at hand, considering the drill bit materials and their geometry, and carefully selecting the ideal size and type, achieving successful drilling outcomes becomes quite manageable. For a successful drilling project, we suggest seeking advice from a renowned Singapore hardware store. Chee Fatt has over decades of experience in distributing a wide range of drilling tools and drill bits from renowned brands. You can source any tools you need from our Singapore hardware store online to tackle any emergency plumbing tasks.

1556

1556